Vacuum Carburizing

Controlled and Reproducible

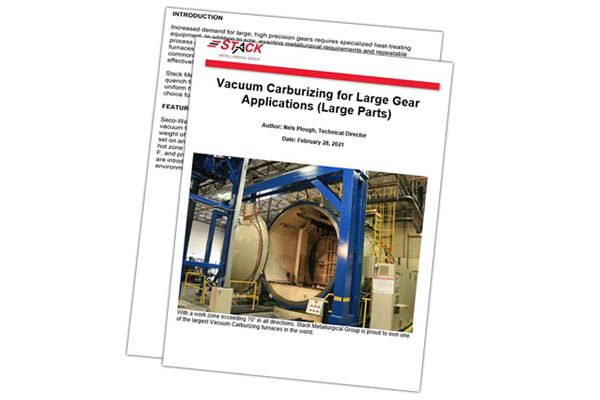

Vacuum carburizing provides customers with complete uniformity by allowing us specify details for case depth, surface and core hardness, carbon profiles, and core microstructure. Parts emerge from this process essentially free of intergranular attack or other surface reactions, and consequently do not post heat treat grinding operations. Our Portland location is home to one of the world’s largest vacuum carburizing furnaces, with a working zone of 70” x 70” x 84” and with a load capacity up to 10,000 lbs.

Benefits of Vacuum Carburizing

| Eliminates surface intergranular oxidation |

| Excellent case uniformity for complex geometries |

| Precise, alloy-specific process controls |

| Highly repeatable case depth control |

Download A Industry Leading Vacuum Carburizing White Paper

Vacuum Carburizing for Large Gear Applications (Large Parts) White Paper

By Nels Plough, Technical Director, Stack Metallurgical Group

Primary Industries

Gear

Power Generation